|

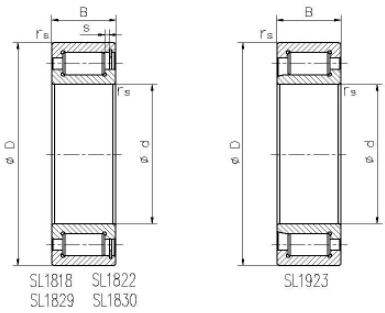

Designation |

Boundary Dimension(mm) |

Basic Load ratings(KN) |

Limiting Speed r/min |

Weight |

|||||

|

d |

D |

B |

rsmin |

s |

Cr |

Cor |

(kg) |

||

|

SL183004 |

20 |

42 |

16 |

0.6 |

1.5 |

27.5 |

26.5 |

9000 |

0.11 |

|

SL182204 |

20 |

47 |

18 |

1 |

1 |

41 |

37.5 |

7000 |

0.16 |

|

SL183005 |

25 |

47 |

16 |

0.6 |

1.5 |

31.5 |

32.5 |

7500 |

0.12 |

|

SL182205 |

25 |

52 |

18 |

1 |

1 |

46 |

45 |

6000 |

0.18 |

|

SL192305 |

25 |

62 |

24 |

1.1 |

2 |

63 |

57 |

4500 |

0.37 |

|

SL83006 |

30 |

55 |

19 |

1 |

2 |

40.5 |

43 |

6500 |

0.2 |

|

SL182206 |

30 |

62 |

20 |

1 |

1 |

61 |

63 |

5000 |

0.3 |

|

SL192306 |

30 |

72 |

27 |

1.1 |

2 |

87 |

85 |

3800 |

0.56 |

|

SL183007 |

35 |

62 |

20 |

1 |

2 |

49.5 |

55 |

5500 |

0.26 |

|

SL182207 |

35 |

72 |

23 |

1.1 |

1 |

76 |

77 |

4300 |

0.44 |

|

SL192307 |

35 |

80 |

31 |

1.5 |

2 |

113 |

112 |

3400 |

0.74 |

|

SL183008 |

40 |

68 |

21 |

1 |

2 |

59 |

68 |

5000 |

0.31 |

|

SL183008 |

40 |

68 |

21 |

1 |

2 |

59 |

68 |

5000 |

0.31 |

|

SL182208 |

40 |

80 |

23 |

1.1 |

1 |

84 |

89 |

3800 |

0.55 |

|

SL192308 |

40 |

90 |

33 |

1.5 |

2 |

152 |

155 |

3000 |

1.01 |

|

SL183009 |

45 |

75 |

23 |

1 |

2 |

63 |

76 |

4600 |

0.4 |

|

SL182209 |

45 |

85 |

23 |

1.1 |

1 |

88 |

96 |

3600 |

0.59 |

|

SL192309 |

45 |

100 |

36 |

1.5 |

3 |

162 |

165 |

2700 |

1.37 |

|

SL183010 |

50 |

80 |

23 |

1 |

2 |

77 |

92 |

4300 |

0.43 |

|

SL182210 |

50 |

90 |

23 |

1.1 |

1 |

95 |

109 |

3300 |

0.64 |

|

SL192310 |

50 |

110 |

40 |

2 |

3 |

205 |

215 |

2500 |

1.81 |

|

SL183011 |

55 |

90 |

26 |

1.1 |

2 |

105 |

134 |

3700 |

0.64 |

|

SL182211 |

55 |

100 |

25 |

1.5 |

1.5 |

122 |

145 |

3000 |

0.87 |

|

SL192311 |

55 |

120 |

43 |

2 |

3 |

242 |

255 |

2300 |

2.28 |

|

SL182912 |

60 |

85 |

16 |

1 |

1 |

54 |

74 |

3800 |

0.29 |

|

SL183012 |

60 |

95 |

26 |

1.1 |

2 |

108 |

141 |

3500 |

0.69 |

|

SL182212 |

60 |

110 |

28 |

1.5 |

1.5 |

152 |

179 |

2700 |

1.18 |

|

SL192312 |

60 |

130 |

46 |

2.1 |

3 |

260 |

280 |

2100 |

2.88 |

|

SL182913 |

65 |

90 |

16 |

1 |

1 |

57 |

81 |

3500 |

0.31 |

|

SL183013 |

65 |

100 |

26 |

1.1 |

2 |

113 |

154 |

3200 |

0.73 |

|

SL182213 |

65 |

120 |

31 |

1.5 |

1.5 |

177 |

213 |

2500 |

1.57 |

|

SL192313 |

65 |

140 |

48 |

2.1 |

3.5 |

315 |

355 |

1900 |

3.52 |

|

SL182914 |

70 |

100 |

19 |

1 |

1 |

76 |

108 |

3200 |

0.49 |

|

SL183014 |

70 |

110 |

30 |

1.1 |

3 |

134 |

171 |

3100 |

1.02 |

|

SL182214 |

70 |

125 |

31 |

1.5 |

1.5 |

183 |

226 |

2400 |

1.66 |

|

SL192314 |

70 |

150 |

51 |

2.1 |

3.5 |

345 |

390 |

1800 |

4.33 |

|

SL182915 |

75 |

105 |

19 |

1 |

1 |

78 |

116 |

3000 |

0.52 |

|

SL183015 |

75 |

115 |

30 |

1.1 |

3 |

141 |

188 |

2800 |

1.06 |

|

SL182215 |

75 |

130 |

31 |

1.5 |

1.5 |

190 |

239 |

2300 |

1.75 |

|

SL192315 |

75 |

160 |

55 |

2.1 |

3.5 |

410 |

475 |

1700 |

5.3 |

|

SL182916 |

80 |

110 |

19 |

1 |

1 |

81 |

123 |

2900 |

0.55 |

|

SL183016 |

80 |

125 |

34 |

1.1 |

4 |

173 |

224 |

2600 |

1.43 |

|

SL182216 |

80 |

140 |

33 |

2 |

1.5 |

223 |

280 |

2100 |

2.15 |

|

SL192316 |

80 |

170 |

58 |

2.1 |

3.5 |

480 |

560 |

1600 |

6.32 |

|

SL182917 |

85 |

120 |

22 |

1.1 |

1 |

102 |

155 |

2700 |

0.81 |

|

SL183017 |

85 |

130 |

34 |

1.1 |

4 |

178 |

235 |

2500 |

1.51 |

|

SL182217 |

85 |

150 |

36 |

2 |

1.5 |

255 |

320 |

2000 |

2.74 |

|

SL192317 |

85 |

180 |

60 |

3 |

4 |

510 |

620 |

1500 |

7.34 |

|

SL182918 |

90 |

125 |

22 |

1.1 |

1 |

106 |

165 |

2500 |

0.84 |

|

SL183018 |

90 |

140 |

37 |

1.5 |

4 |

207 |

280 |

2300 |

1.97 |

|

SL182218 |

90 |

160 |

40 |

2 |

2.5 |

285 |

365 |

1900 |

3.48 |

|

SL192318 |

90 |

190 |

64 |

3 |

4 |

560 |

660 |

1400 |

8.83 |

|

SL182919 |

95 |

130 |

22 |

1.1 |

1 |

114 |

172 |

2400 |

0.86 |

|

SL182219 |

95 |

170 |

43 |

2.1 |

2.5 |

335 |

430 |

1700 |

4.17 |

|

SL192319 |

95 |

200 |

67 |

3 |

4 |

580 |

720 |

1350 |

10.2 |

|

SL182920 |

100 |

140 |

24 |

1.1 |

1.5 |

132 |

199 |

2300 |

1.14 |

|

SL183020 |

100 |

150 |

37 |

1.5 |

4 |

218 |

305 |

2200 |

2.15 |

|

SL182220 |

100 |

180 |

46 |

2.1 |

2.5 |

390 |

520 |

1600 |

5.13 |

|

SL192320 |

100 |

215 |

73 |

3 |

4 |

710 |

860 |

1300 |

13 |

|

SL182922 |

110 |

150 |

24 |

1.1 |

1.5 |

137 |

213 |

2100 |

1.23 |

|

SL183022 |

110 |

170 |

45 |

2 |

5.5 |

285 |

395 |

2000 |

3.5 |

|

SL182222 |

110 |

200 |

53 |

2.1 |

4 |

455 |

590 |

1500 |

7.24 |

|

SL192322 |

110 |

240 |

80 |

3 |

5 |

840 |

970 |

1150 |

17 |

|

SL182924 |

120 |

165 |

27 |

1.1 |

1.5 |

176 |

285 |

1900 |

1.73 |

|

SL183024 |

120 |

180 |

46 |

2 |

5.5 |

300 |

435 |

1800 |

3.8 |

|

SL182224 |

120 |

215 |

58 |

2.1 |

4 |

530 |

730 |

1400 |

9.08 |

|

SL192324 |

120 |

260 |

86 |

3 |

5 |

990 |

1220 |

1050 |

22.3 |

|

SL182926 |

130 |

180 |

30 |

1.5 |

2 |

210 |

350 |

1800 |

2.33 |

|

SL183026 |

130 |

200 |

52 |

2 |

5.5 |

430 |

610 |

1700 |

5.65 |

|

SL182226 |

130 |

230 |

64 |

3 |

5 |

630 |

860 |

1300 |

11.25 |

|

SL182928 |

140 |

190 |

30 |

1.5 |

2 |

228 |

375 |

1600 |

2.42 |

|

SL183028 |

140 |

210 |

53 |

2 |

5.5 |

455 |

670 |

1500 |

6.04 |

|

SL182228 |

140 |

250 |

68 |

3 |

5 |

720 |

1020 |

1200 |

14.47 |

|

SL182930 |

150 |

210 |

36 |

2 |

2.5 |

305 |

490 |

1500 |

3.77 |

|

SL183030 |

150 |

225 |

56 |

2.1 |

7 |

475 |

700 |

1500 |

7.33 |

|

SL182230 |

150 |

270 |

73 |

3 |

6 |

830 |

1180 |

1100 |

18.43 |

|

SL182932 |

160 |

220 |

36 |

2 |

2.5 |

320 |

520 |

1400 |

4 |

|

SL183032 |

160 |

240 |

60 |

2.1 |

7 |

540 |

810 |

1400 |

8.8 |

|

SL182232 |

160 |

290 |

80 |

3 |

6 |

1020 |

1460 |

1000 |

23 |

|

SL182934 |

170 |

230 |

36 |

2 |

2.5 |

330 |

560 |

1300 |

4.3 |

|

SL183034 |

170 |

260 |

67 |

2.1 |

7 |

710 |

1070 |

1300 |

12.2 |

|

SL182234 |

170 |

310 |

86 |

4 |

7 |

1140 |

1660 |

950 |

28.65 |

|

SL182936 |

180 |

250 |

42 |

2 |

2.5 |

410 |

690 |

1300 |

6.2 |

|

SL183036 |

180 |

280 |

74 |

2.1 |

7 |

820 |

1260 |

1200 |

16.1 |

|

SL182236 |

180 |

320 |

86 |

4 |

7 |

1180 |

1760 |

900 |

29.8 |

|

SL182938 |

190 |

260 |

42 |

2 |

2.5 |

455 |

790 |

1200 |

6.5 |

|

SL183038 |

190 |

290 |

75 |

2.1 |

9 |

840 |

1320 |

1100 |

17 |

|

SL182238 |

190 |

340 |

92 |

4 |

9 |

1300 |

1900 |

850 |

35.65 |

|

SL181840 |

200 |

250 |

24 |

1.5 |

2 |

178 |

320 |

1200 |

2.57 |

|

SL182940 |

200 |

280 |

48 |

2.1 |

3 |

550 |

940 |

1100 |

9.1 |

|

SL183040 |

200 |

310 |

82 |

2.1 |

9 |

960 |

1530 |

1100 |

21.8 |

|

SL182240 |

200 |

360 |

98 |

4 |

9 |

1420 |

2040 |

850 |

43.12 |

|

SL181844 |

220 |

270 |

24 |

1.5 |

2 |

187 |

350 |

1100 |

2.8 |

|

SL182944 |

220 |

300 |

48 |

2.1 |

3 |

570 |

1040 |

1000 |

9.9 |

|

SL183044 |

220 |

340 |

90 |

3 |

9 |

1150 |

1810 |

1000 |

28.4 |

|

SL181848 |

240 |

300 |

28 |

2 |

3 |

212 |

405 |

1000 |

4.4 |

|

SL182948 |

240 |

320 |

48 |

2.1 |

3 |

600 |

1130 |

950 |

10.6 |

|

SL183048 |

240 |

360 |

92 |

3 |

11 |

1210 |

1990 |

900 |

30.9 |

|

SL181852 |

260 |

320 |

28 |

2 |

3 |

222 |

440 |

950 |

4.71 |

|

SL182952 |

260 |

360 |

60 |

2.1 |

3.5 |

790 |

1460 |

900 |

18.5 |

|

SL183052 |

260 |

400 |

104 |

4 |

11 |

1620 |

2550 |

800 |

44.5 |

|

SL181856 |

280 |

350 |

33 |

2 |

3 |

305 |

600 |

850 |

7 |

|

SL182956 |

280 |

380 |

60 |

2.1 |

3.5 |

920 |

1740 |

800 |

19.7 |

|

SL183056 |

280 |

420 |

106 |

4 |

11 |

1660 |

2700 |

800 |

48 |

|

SL181860 |

300 |

380 |

38 |

2.1 |

3.5 |

375 |

730 |

800 |

10 |

|

SL182960 |

300 |

420 |

72 |

3 |

5 |

1180 |

2230 |

750 |

31.2 |

|

SL183060 |

300 |

460 |

118 |

4 |

14 |

2040 |

3350 |

700 |

66.6 |

|

SL181864 |

320 |

400 |

38 |

2.1 |

4.5 |

385 |

780 |

750 |

10.6 |

|

SL182964 |

320 |

440 |

72 |

3 |

5 |

1220 |

2360 |

700 |

32.9 |

|

SL183064 |

320 |

480 |

121 |

4 |

14 |

2090 |

3500 |

650 |

71.7 |

|

SL181868 |

340 |

420 |

38 |

2.1 |

4.5 |

395 |

820 |

700 |

11.2 |

|

SL182968 |

340 |

460 |

72 |

3 |

5 |

1260 |

2500 |

700 |

34.7 |

|

SL183068 |

340 |

520 |

133 |

5 |

16 |

2490 |

4150 |

600 |

95.8 |

|

SL181872 |

360 |

440 |

38 |

2.1 |

4.5 |

410 |

870 |

650 |

11.7 |

|

SL182972 |

360 |

480 |

72 |

3 |

5 |

1290 |

2650 |

650 |

36.4 |

|

SL183072 |

360 |

540 |

134 |

5 |

16 |

2550 |

4350 |

550 |

101 |

|

SL181876 |

380 |

480 |

46 |

2.1 |

6 |

570 |

1150 |

600 |

19.2 |

|

SL182976 |

380 |

520 |

82 |

4 |

5 |

1670 |

3300 |

600 |

52.1 |

|

SL183076 |

380 |

560 |

135 |

5 |

16 |

2650 |

4550 |

550 |

106 |

|

SL181880 |

400 |

500 |

46 |

2.1 |

6 |

590 |

1220 |

600 |

20 |

|

SL182980 |

400 |

540 |

82 |

4 |

5 |

1720 |

3500 |

550 |

54.3 |

|

SL183080 |

400 |

600 |

148 |

5 |

18 |

3100 |

5500 |

500 |

140 |

|

SL181884 |

420 |

520 |

46 |

2.1 |

6 |

600 |

1260 |

550 |

20.9 |

|

SL182984 |

420 |

560 |

82 |

4 |

5 |

1750 |

3600 |

550 |

56.9 |

|

SL181888 |

440 |

540 |

46 |

2.1 |

6 |

610 |

1320 |

550 |

21.8 |

|

SL182988 |

440 |

600 |

95 |

4 |

7 |

2130 |

4200 |

500 |

78.1 |

|

SL181892 |

460 |

580 |

56 |

3 |

7 |

790 |

1660 |

500 |

33.9 |

|

SL182992 |

460 |

620 |

95 |

4 |

7 |

2160 |

4350 |

500 |

81.1 |

|

SL181896 |

480 |

600 |

56 |

3 |

7 |

800 |

1720 |

500 |

35.2 |

|

SL182996 |

480 |

650 |

100 |

5 |

7 |

2430 |

4900 |

480 |

94.7 |

|

SL1818/500 |

500 |

620 |

56 |

3 |

7 |

820 |

1810 |

480 |

36.5 |

|

SL1829/500 |

500 |

670 |

100 |

5 |

7 |

2460 |

5100 |

460 |

98.3 |

.jpg)