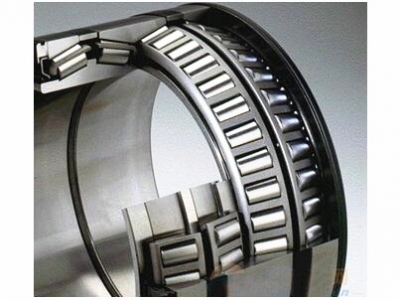

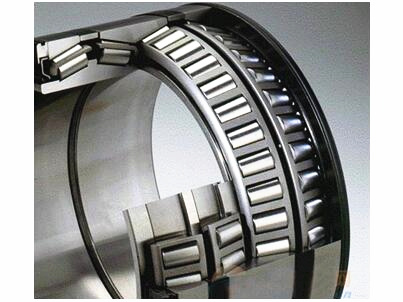

Four Row Tapered Cylindrical Roller Bearings

|

Designation |

Boundary Dimension(mm) |

Basic loadratings |

Limiting Speed r/min |

Mass |

||||||||

|

New Code |

Old Code |

d |

D |

B |

T |

rsmin |

r1smin |

Cr(KN) |

Cor(KN) |

Grease |

Oil |

(Kg) |

| 382952 | 2077952 | 260 | 360 | 265 | 265 | 3 | 2.5 | 1920 | 4590 | 450 | 560 | 76.3 |

| 382052 | 2077152 | 260 | 400 | 345 | 345 | 5 | 4 | 3750 | 7950 | 430 | 530 | 153 |

| 381156 | 1077756 | 280 | 460 | 324 | 324 | 5 | 4 | 4100 | 7850 | 360 | 450 | 200 |

| 382960 | 2077960 | 300 | 420 | 300 | 300 | 4 | 3 | 2253 | 4702 | 380 | 480 | 130 |

| 382060 | 2077160 | 300 | 460 | 390 | 390 | 5 | 4 | 3234 | 6832 | 360 | 450 | 238 |

| 381160 | 1077760 | 300 | 500 | 370 | 370 | 5 | 4 | 3654 | 6776 | 340 | 430 | 285 |

| 382064/YB2 | 2077164 | 320 | 480 | 380 | 380 | 5 | 4 | 3234 | 8296 | 340 | 430 | 234 |

| 382968 | 2077968 | 340 | 460 | 310 | 310 | 4 | 3 | 2478 | 5782 | 340 | 430 | 145 |

| 380068 | 77168 | 340 | 520 | 325 | 325 | 5 | 4 | 2898 | 5872 | 320 | 400 | 234 |

| 381168 | 1077768 | 340 | 580 | 425 | 425 | 5 | 4 | 4236 | 8450 | 280 | 360 | 441 |

| 380072 | 77172 | 360 | 540 | 325 | 325 | 5 | 4 | 3388 | 6524 | 300 | 380 | 248 |

| 380076 | 77176 | 380 | 560 | 325 | 325 | 5 | 4 | 3066 | 5754 | 280 | 380 | 281 |

| 381176 | 1077776 | 380 | 620 | 420 | 420 | 5 | 4 | 5082 | 9604 | 240 | 360 | 519 |

| 380080 | 77180 | 400 | 600 | 356 | 356 | 5 | 4 | 2618 | 6762 | 240 | 320 | 317 |

| 380084 | 77184 | 420 | 620 | 356 | 356 | 5 | 4 | 3948 | 7616 | 220 | 300 | 358 |

| 381184 | 1077784 | 420 | 700 | 480 | 480 | 6 | 5 | 7308 | 12360 | 190 | 260 | 760 |

| 380088 | 77188 | 440 | 650 | 376 | 376 | 6 | 5 | 4326 | 9072 | 200 | 280 | 401 |

| 381992 | 1077992 | 460 | 620 | 310 | 310 | 4 | 3 | 3402 | 7350 | 200 | 280 | 173 |

| 380092 | 77192 | 460 | 680 | 410 | 410 | 6 | 5 | 5665 | 11235 | 180 | 240 | 476 |

| 381996 | 1077996 | 480 | 650 | 338 | 338 | 5 | 4 | 3390 | 10500 | 190 | 260 | 301 |

| 380096 | 77196 | 480 | 700 | 420 | 420 | 6 | 5 | 5922 | 12600 | 170 | 220 | 547 |

| 3800/500 | 771/500 | 500 | 720 | 420 | 420 | 6 | 5 | 5950 | 12768 | 160 | 200 | 565 |

| 3800/530 | 771/530 | 530 | 780 | 450 | 450 | 6 | 5 | 7602 | 15960 | 140 | 180 | 744 |

| 3811/530 | 10777/530 | 530 | 870 | 590 | 590 | 7.5 | 6 | 10038 | 20300 | 110 | 160 | 1422 |

| 3819/560 | 10779/560 | 560 | 750 | 368 | 368 | 5 | 4 | 4424 | 10374 | 140 | 180 | 456 |

| 3811/560 | 10777/560 | 560 | 920 | 620 | 620 | 7.5 | 6 | 12138 | 20300 | 100 | 140 | 1635 |

| 3819/600 | 10779/600 | 600 | 800 | 380 | 380 | 5 | 4 | 4728 | 11652 | 120 | 160 | 536 |

| 3800/600 | 771/600 | 600 | 870 | 480 | 480 | 6 | 5 | 7212 | 15960 | 100 | 140 | 995 |

| 3811/600 | 10777/600 | 600 | 980 | 650 | 650 | 7.5 | 6 | 11808 | 24480 | 90 | 120 | 1970 |

| 3819/630 | 10779/630 | 630 | 850 | 418 | 418 | 6 | 5 | 7472 | 17600 | 100 | 140 | 720 |

| 3800/630 | 771/630 | 630 | 920 | 515 | 515 | 7.5 | 6 | 9975 | 20860 | 95 | 130 | 1158 |

| 3811/630 | 10777/630 | 630 | 1030 | 670 | 670 | 7.5 | 6 | 10755 | 31080 | 85 | 110 | 2170 |

| 3819/670 | 10779/670 | 670 | 900 | 412 | 412 | 6 | 5 | 7545 | 17360 | 95 | 130 | 959 |

| 3811/670 | 10777/670 | 670 | 1090 | 710 | 710 | 7.5 | 6 | 15700 | 39900 | 75 | 95 | 2665 |

| 3800/710 | 771/710 | 710 | 1030 | 555 | 555 | 7.5 | 6 | 9828 | 22560 | 75 | 95 | 1568 |

| 3811/710 | 10777/710 | 710 | 1150 | 750 | 750 | 9.5 | 8 | 15840 | 33960 | 67 | 85 | 3227 |

| 3800/750 | 771/750 | 750 | 1090 | 605 | 605 | 7.5 | 6 | 11580 | 26760 | 70 | 90 | 1880 |

| 3811/750 | 10777/750 | 750 | 1220 | 840 | 840 | 9.5 | 8 | 18590 | 41470 | 48 | 80 | 3994 |

| 3820/950 | 20771/950 | 950 | 1360 | 880 | 880 | 7.5 | 6 | 17000 | 44200 | 48 | 80 | 4087 |

| 3820/1060 | 20771/1060 | 1060 | 1500 | 1000 | 1000 | 9.5 | 8 | 21300 | 56300 | 48 | 80 | 5698 |

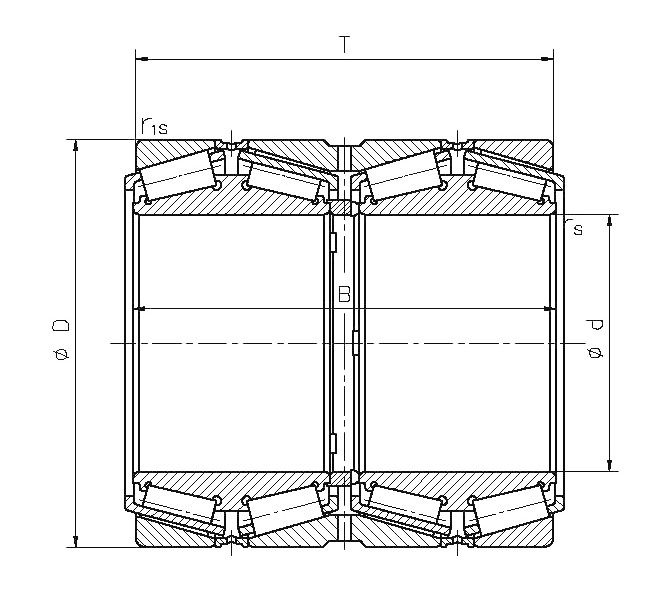

Four-row tapered roller bearings

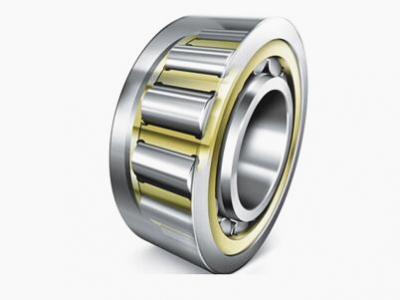

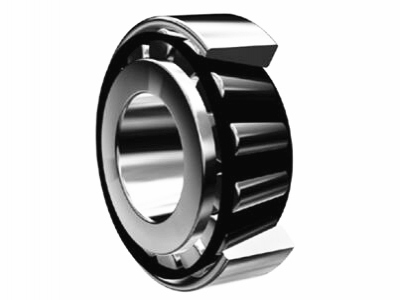

Tapered roller bearings have tapered inner and outer ring raceways and tapered rollers. The bearings are not self-retaining. As a result, the inner ring together with the rollers and cage can be fitted separately from the outer ring. Tapered roller bearings utilize conical rollers and raceways, arranged so that the rollers and raceways meet at a common apex. The rollers are guided by contact between the large end of the roller and a rib on the inner ring. They are designed to accommodate combined loads, i.e. simultaneously acting radial and axial loads. The axial load carrying capacity of tapered roller bearings increases with increasing contact angle (α). The size of the angle is indicated by the calculation factor e :the larger the value of e, the larger the contact angle.

Four-row tapered roller bearings are used successfully worldwide for rolling mill bearing arrangements where rolling speeds are slow to moderate. Because of their design they are able to take up those axial loads which occur in such applications in addition to radial loads and generally no separate thrust bearings are required in such arrangements. This means that the roll necks can be relatively short and the chocks at both sides of the roll can have the same design.

Four-row tapered roller bearings, because of their design, must be installed as complete bearings in the chocks. To enable quick roll changes to be made they must therefore have a loose fit on the roll necks. Loose fits have the disadvantage that the inner rings wander on their seats under the prevailing load conditions causing wear to the seats which normally have a lower hardness than the rings. To alleviate the effects of a loose fit to some extent, i.e. to reduce wear, SKF bearings have a helical groove in the bore and/or lubrication grooves in the side faces of the inner rings. These grooves enable lubricant to be supplied to the contact surfaces of the inner ring and seat. Additionally, the grease-filled grooves can absorb the wear particles.

LYNBC produces an extensive range of four-row tapered roller bearings which covers not only the conventional designs with intermediate rings between the outer and/or inner rings, but also a new design with modified rings which integrate the intermediate rings.

▲ The design’s of all these tapered roller bearings are based on standard structures; LYNBC can design and manufacture many other similar structures in accordance to the special and particular requirements of their customers’. If our customer’s have specific requests then the customer should identify the structure, and mounting dimensions that are required. Please contact the LYNBC Technical Center if you need any assistance in this area.

If you have any suggestions or opinions about our products,please leave a message,and we will immediately answer your questions. Thanks for your support.

Previous Article:Tapered Cylindrical Roller Thrust Bearings

.jpg)